Which HPLC sample vials should you choose for your analysis?

When it comes to analytical High-Performance Liquid Chromatography (HPLC), every analysis starts with a sample vial. Let’s be honest: in most cases, this step doesn’t involve much research or a huge decision-making process. Usually, you open the drawer of your bench under the HPLC, grab a sample vial, pipette in your analyte, close the vial, and place the vial in the autosampler of your HPLC to commence with the “actual” work.

But what if I told you that, depending on the analysis you are trying to run, the instrumentation, and the detection method you are using, you might already have fallen into the pitfall of not choosing the suitable vials for your needs? So maybe your choice has fallen on an expensive and cost-ineffective type of vial, which increases the cost per run on your HPLC. Or the vial material is not suitable for the detection method of your choice. Let´s look at a few aspects you should consider before grabbing the first vial you find in the drawer.

Glass vials quality – a non-negotiable requirement

Your vials can be made of many different materials, but in most cases, they are either made of glass or plastic, specifically polypropylene. In this blog post, I will only focus on HPLC glass vials.

When you choose your vial, you need to consider two parameters of the glass: the chemical composition and a property called linear coefficient of expansion (COE), which describes to which extent the size of an object changes over a temperature range.

Borosilicate glass vs. soda-lime glass

From a chemical perspective, there are two types of glass for HPLC sample vials: borosilicate and soda-lime glass. Borosilicate contains silica (SiO2) and boron trioxide (B2O3) and is known for its high thermal and chemical resistance. Soda-lime glass, on the other hand, is made from silica (SiO2), sodium oxide (Na2O), and calcium oxide, also called lime (CaO). It is the most used glass for glass containers.

Due to its special stability and high resistance to leaching, borosilicate glass is the preferred material for HPLC sample vials over soda-lime glass.

33, 51, or 70?

Glass materials are further classified based on the coefficient of expansion (COE). Simply said, the lower the value, the lower the level of leachable and free ion content, and therefore, the higher the quality of the glass.

Borosilicate glass is then categorized again into two different types: 33 and 51. These numbers refer to the COE of these glass types. Soda-lime glasses have a COE of 70 and above.

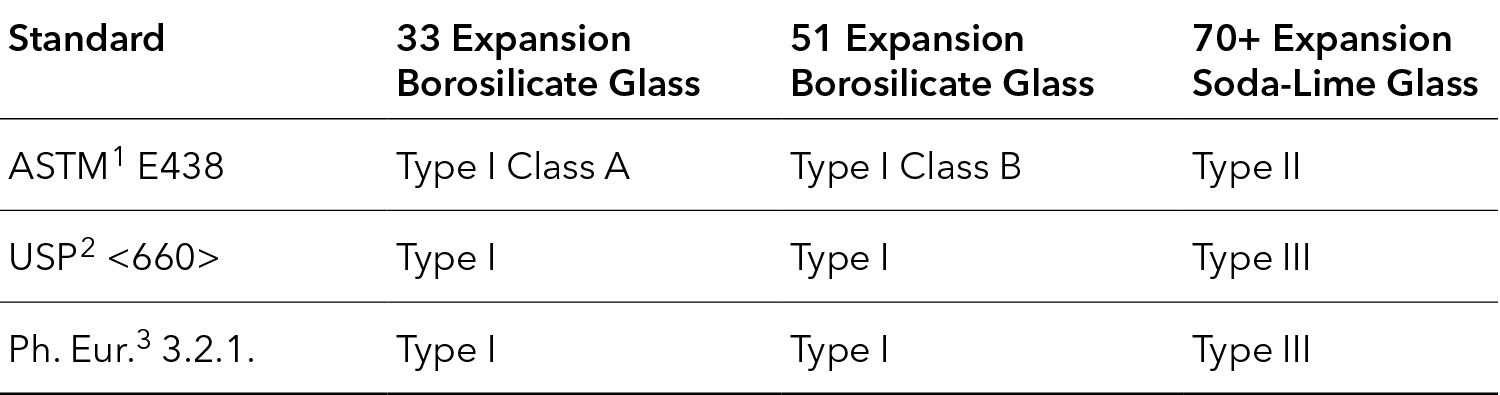

Depending on the standardization, these glass types are classified as Type I/II/III, Class A/ Class B. The table below provides an overview.

1 American Society for Testing and Materials (E438 Standard Specification for Glasses in Laboratory Apparatus [astm.org]) 2 United States Pharmacopeia 3 European Pharmacopeia

Borosilicate glass 33 and 51 are used for HPLC sample vials in labs around the world, and in general, there is one thing you should take home from this for your HPLC analysis:

Another tip: be aware that clear glass vials are produced in 33 and 51 qualities, but amber vials don’t! Amber vials always have a COE of at least 51.

Enough material chemistry talk for now, but the quality of HPLC sample vials is not solely defined by the composition of its glass.

The detection method is key

Let's put it as simple as it is:

Quality is relative; make wise investments!

This might sound like a bold statement, but it’s crucial to understand what it means in the context of HPLC analysis. Depending on the method you’re using, whether it’s UV detection, mass spectrometry (MS), or any other technique, the quality requirements for your sample vials can significantly vary.

Here are a few examples: if your analysis relies on UV detection, you might not notice any difference between using MS-certified vials and UV-certified ones.

MS-certified vials are designed to meet MS' demands, ensuring that no contaminants interfere with the detection of low-abundance analytes. Usually, these vials undergo rigorous testing to certify that they won’t leach any substances that could compromise the sensitivity of MS detection.

On the other hand, standard vials, which undergo regular quality control by the manufacturer, might be sufficient for most applications, as with MS detection.

However, switching to a method like MS/MS, where the detection sensitivity is even higher, using UV-certified or non-certified vials might result in inconsistent results. These vials might not meet the low-level contamination thresholds required for MS/MS, potentially leading to ghost peaks or signal suppression.

In this case, investing in MS-certified vials is essential to maintain the integrity of your results.

When choosing glass HPLC sample vials, first, you should make sure to use borosilicate glass vials. Then, the quality should correlate with the demands of your analysis.

For standard analyses, such as those using UV detection, investing in 51-expansion borosilicate is the best choice to guarantee the required quality level at an affordable price.

If your work involves trace analysis with highly sensitive techniques like LC-MS/MS, selecting 33-expansion borosilicate glass vials ensures that no contaminants interfere with detecting low-abundance analytes, providing the reliability and consistency necessary for accurate results.

Understanding the difference in HPLC sample vials

In the end, the next time you need a vial, do not just grab the first one from the drawer; instead, ask yourself if it matches your analytical requirements.

Making the right choice can mean the difference between dependable data and results that leave you questioning your entire analysis.

If you want to optimize your HPLC workflow, check out our brand-new KNAUER originals HPLCsample vials.

For further information on this topic, don't hesitate to get in touch with our author:

Dr. Jakob Leppkes leppkes@knauer.net